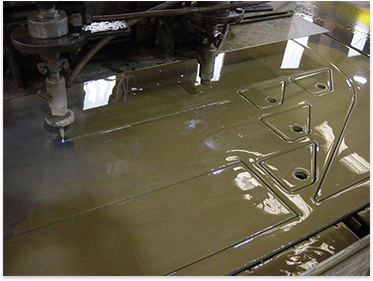

Water Jet Cutting

Applications

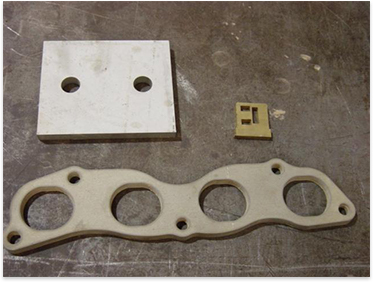

Can cut a wider variety of materials than either laser or EDM machining including reflective materials such as aluminum or copper with precision tolerances. CNC and multi-axis cutting is available.

Advantages

Comparable to laser cutting tolerances and faster than EDM machining with lower capital and operating costs, water jet cutting is also environmentally advantageous and provides many other benefits.

- No Heat Affected Zone

- Narrow Kerf – .002-.040

- Intricate Cuts

- High Production or Single Piece

- No Tooling Changes

- Fast Set-up

Technology

An ultra high pressure (>30,00psi) and high velocity water stream containing abrasives is forced through a jeweled orifice creating a fine water jet which can cut virtually any material. The water pressure, velocity and abrasives combine to literally erode the work piece creating the cut.

Specifications

- Max Cut Size 6′ x 12′

- 10″ thick cutting capacity